Now in the optical cable industry, there are many large and small optical cable manufacturers, so for small white customers outside the industry, how to choose a satisfactory optical cable manufacturer that can reassure customers? Those are all optical cable manufacturers. What is the quality difference between the optical cables produced? Today, as an optical cable manufacturer, I will unveil the chaos in the optical cable industry. Many optical cable manufacturers are trying to reduce costs and compete at low prices. They must reduce costs. If they reduce costs, they will definitely cut corners and replace pillars.

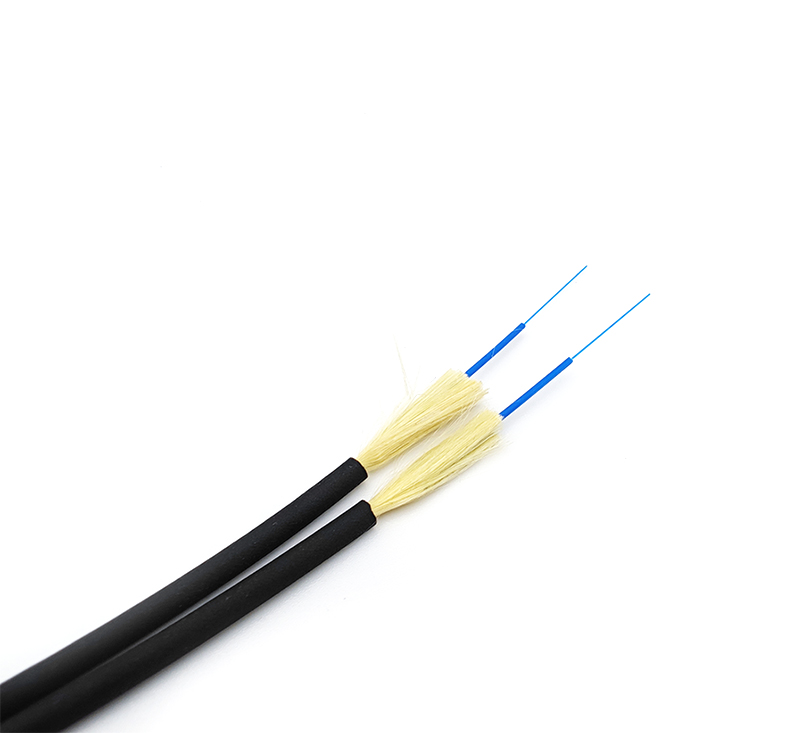

Let's first talk about the optical fibers in the optical cable. The optical fibers our optical cable manufacturers use are YOFC, FiberHome, Futong and other A-grade fibers. Some manufacturers use C-grade fibers, which are the unqualified ones selected from the B-grade fibers. Optical fiber, this kind of optical fiber has large loss, insufficient roundness of optical fiber, easy to break, and difficult to splicing.

The ointment in the optical cable, whether the ointment is good or not mainly depends on whether the optical cable has water blocking properties, and whether it will corrode the steel wire, steel armor, and aluminum armor. Our optical cable manufacturers all use the new national standard water-blocking ointment. The produced optical cables will be tested for water seepage, and only qualified products can leave the factory.

Optical cable manufacturers use loose tubes made of high-modulus polyester materials, PBT with good hydrolysis resistance and high strength, and some manufacturers will use materials such as PP to reduce costs.

The central reinforcement we use is phosphated steel wire and high-density non-metallic FRP material. The armor is made of aluminum armor and double-coated steel armor. These materials we use have anti-corrosion, anti-moisture permeability, anti-pressure, tensile strength and other properties. We use a new PE sheath material on the sheath. UV resistance, thermal oxygen aging resistance, environmental stress crack resistance, no weathering, electrical corrosion resistance and other properties. Some manufacturers use recycled old materials, the color of the sheath material is dark, not resistant to rain, easy to corrode, and has a short service life.