Optical fiber is the abbreviation of optical fiber, which is a kind of fiber made of glass glass or plastic plastic, which can be used as a light transmission tool. With the development of science and technology, optical fiber has defeated copper cables with its superior performance and has become an important transmission medium for network backbone lines.

At present, the use of optical fibers is becoming more and more extensive, and products such as optical fiber accessories used with optical fibers are constantly emerging. The technology related to optical fibers has become more and more mature with the wide application of optical fibers, among which the fusion splicing technology of optical fibers is one of them. one:

In the process of optical fiber fusion, in order to make the connection between optical fibers better, a new product appeared: optical fiber heat shrinkable tube. Here we introduce how to use the optical fiber heat shrinkable tube.

1. Strip the outer layer of the optical cable.

During the operation, rotate the sheath cutting knife, at the same time pay attention to observe the incision, see the white polyester tape, stop the knife feeding and remove the cutting knife.

2. Fix the optical cable and pay attention to the core fiber bundle tube.

After the outer layer of the optical cable is stripped, the optical cable needs to be fixed in the optical cable splice box. Strip the core tube. Make preparations before fiber splicing.

Therefore, it is generally advisable to strip it to the two fixed bayonets. At this length, the fiber core bundle will not cause damage to the optical fiber, and it can also be well fixed. However, the clips of the optical fiber heat shrinkable tube should not be too tight when fixing, otherwise the optical fiber of the core bundle tube will increase the loss due to the force, and the optical fiber will break after a long time, leaving hidden dangers to the project.

3. Fiber fusion.

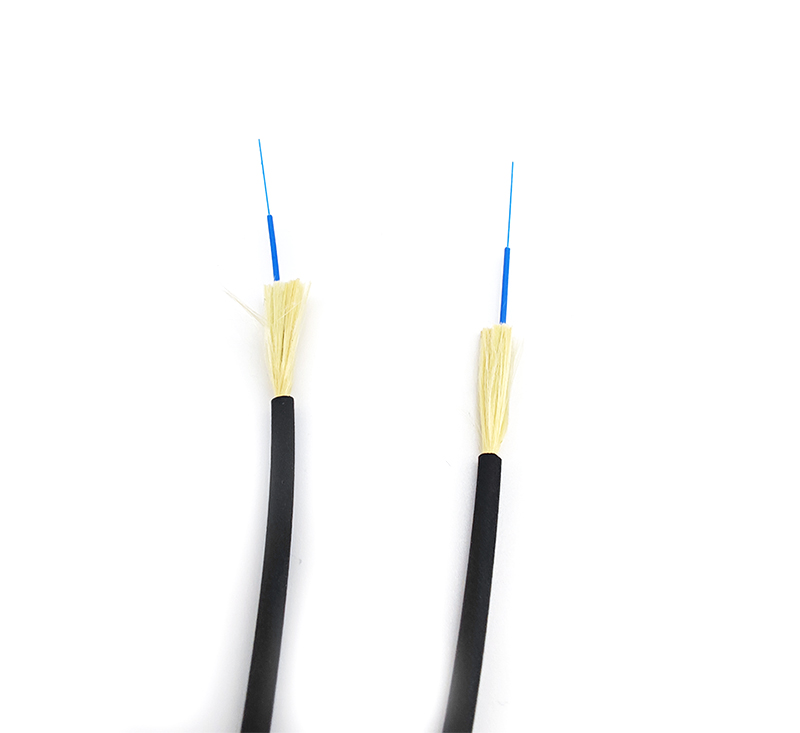

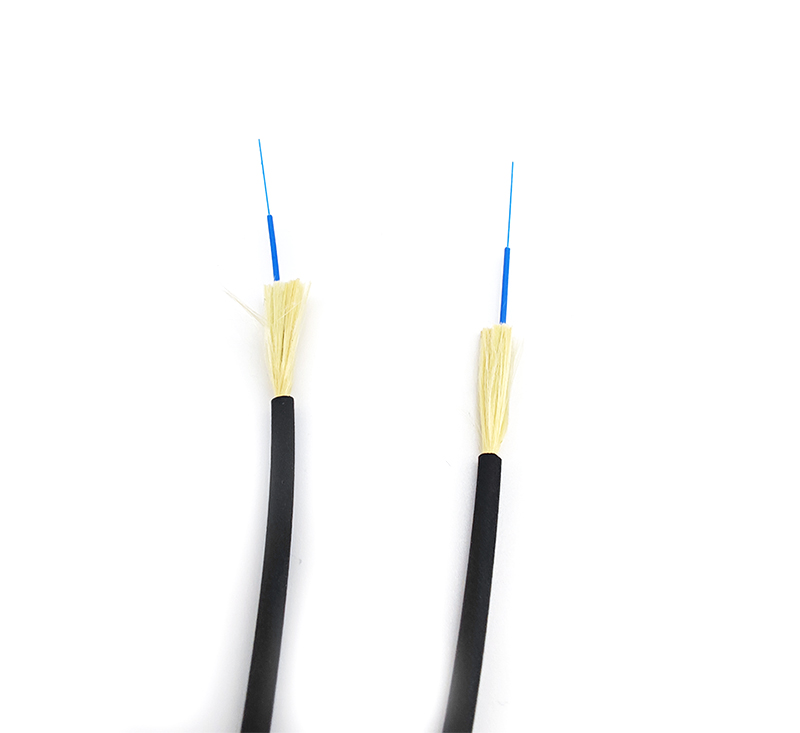

The connection of optical fiber is directly related to the quality and life of the project, and the key lies in the preparation of the fiber end face. The fiber end face is smooth without burrs or defects, and the fusion splicer can accept the confirmation well and can make joints that meet the engineering requirements. Meet engineering requirements. The fusion splicer is the key equipment for optical fiber fusion, and it is also a high-precision and expensive equipment. In the process of use, it must be operated in strict accordance with the regulations, otherwise it may cause heavy losses. Special attention should be paid to the operation procedure of the fusion splicer, and the length setting of the optical fiber heat shrinkable tube should meet the requirements.

4. Protection of residual fibers.

After the optical fiber is spliced, it is necessary to protect the optical fiber with a heat-shrinkable tube and to keep the remaining fiber.

A. During the fiber coiling process, the bending radius of the coil fiber should not be too small, generally not less than 4mm. If the bending radius is too small, it is easy to cause excessive refraction loss and increased dispersion. Over time, fiber breakage may also occur.

B. When coiling the fiber, pay attention to the twisting direction of the fiber, which is generally an inverted "8" shape. Be careful not to twist the fiber. After the coil is completed, put all the fiber under the baffle of the receiving tray to avoid damage to the fiber during packaging.

5. Sealing of the joint box.

In the actual integrated wiring project, the sealing of the optical cable splice box is very important. Because if the splice box of the optical cable enters the water, the optical fiber shows that it is easy to produce micro cracks. If it is soaked in water for a long time, the optical fiber will be broken, and the cable splice box is mostly buried underground. So the joint box sealing is very important.