Product acceptance and quality identification

When the user accepts the product, he can identify it from the following aspects to judge whether the product meets the standard. Considering that it is unlikely that users have professional testing equipment, several simple and effective methods are introduced:

1. At present, the main materials of security cables are copper and polyvinyl chloride (PVC). The quality of the material can be identified with the naked eye.

1) The copper conductor must be shiny, soft and stretchy. On the contrary, the copper conductor has poor gloss and blackening, or has been oxidized, and the conductor that breaks with a slight pull by hand may be an unqualified product.

2) The surface of PVC material should be smooth, flat and clean. If the surface is rough, it not only indicates that the plastic material, processing technology and plasticizing performance are poor, but at the same time, if the plastic surface has large pores, it is easy to be affected by moisture and affect the performance of the product. In addition, the tensile strength of the plastic is also very important. If it is easy to peel off by hand, it may be a material of unqualified quality.

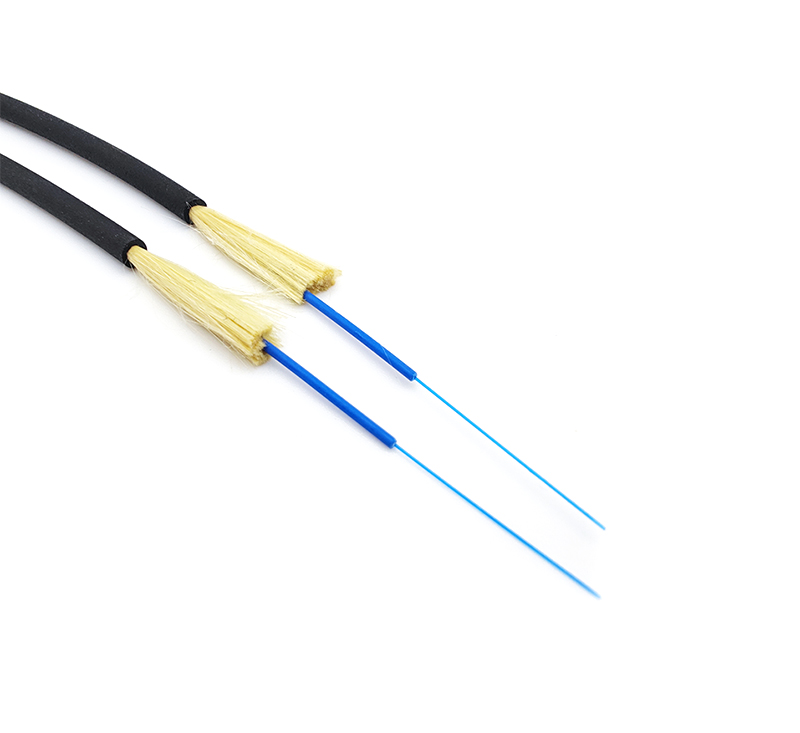

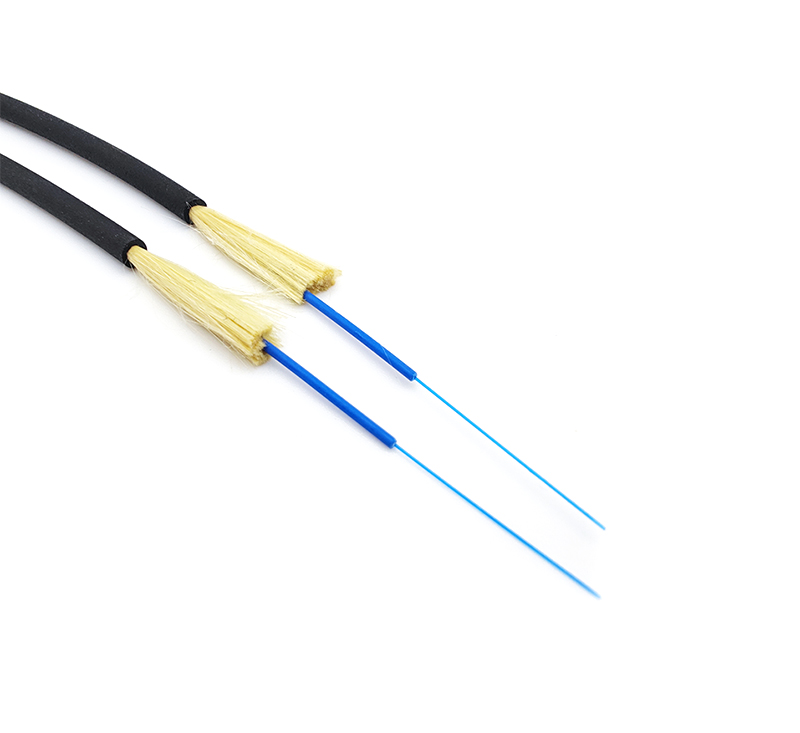

3) Observe whether there is a filler material for tensile protection between the cores of the cable structure. The use of such materials can effectively protect the stability of the internal structure of the cable and improve the tensile strength of the product during engineering construction.

4) Use a micrometer to measure whether the size, thickness, diameter, etc. of the product meet the requirements

2. Structural process inspection

When the user conducts product acceptance, the outer sheath of the cable can be peeled off to test the structure and process of the product. The following items can be focused on:

1) Whether the copper conductor is twisted or not. Irregular manufacturers omit this important process. If the copper conductor is not twisted, the conductor structure will be unstable. When the cable is bent, the construction will easily cause the insulator to crack or the conductor to stab. through the insulating layer.

2) Whether the cabling pitch is too large The cabling pitch refers to the node distance of the multi-core cable after the core wires are twisted during the production process. In order to control costs and improve production speed, some manufacturers tend to enlarge the pitch of cables. Therefore, the flexibility of the product is poor, and the internal structure is unstable, thereby reducing the performance of the cable product.

3) The insulating plastic should be tightly extruded and wrapped on the conductor without damaging the conductor, and the conductor should not be eccentric.

4) The outer sheath is tightly wrapped on the internal structure, and the gap should not be too large. There is a polyester wrapping film between the outer sheath and the internal structure to effectively prevent mutual adhesion.

5) The quality of the shielding structure in the shielded cable is extremely critical to the product in the security system engineering. It is required to cover tightly, regularly and evenly. In addition to the high production process requirements of production enterprises, the production equipment is very critical. At present, several major domestic security cable companies use high-precision PLC-controlled braiding machines. The products produced by this type of equipment have stable structure and regular arrangement. Guaranteed excellent shielding performance.

6) The outer diameter is uniform and the roundness is acceptable. The vast majority of security cables are used in engineering projects. Manufacturers mainly consider stable product structure and excellent and reliable transmission performance, so the roundness of appearance is generally not emphasized deliberately.