Outer sheath: Indoor optical cables are generally made of polyvinylidene or flame-retardant polyvinylidene. The surface should be smooth, bright, flexible and easy to detach. The surface finish of the optical cable with poor quality is not very good, and it is easy to stick to the tight sleeve and aramid fiber inside. The PE sheath of the outdoor optical cable should be made of high-quality gray-black high-pressure polyethylene. After the cable is formed, the outer skin is flat, bright, uniform in thickness, and no air bubbles. The outer sheath of inferior optical cable is generally produced by purchasing raw materials, which can save a lot of cost. The outer sheath of such optical cable is not smooth. Because there are many residues in the raw material, the outer sheath of the optical cable made has many tiny pits, which will crack after a long time. , seepage.

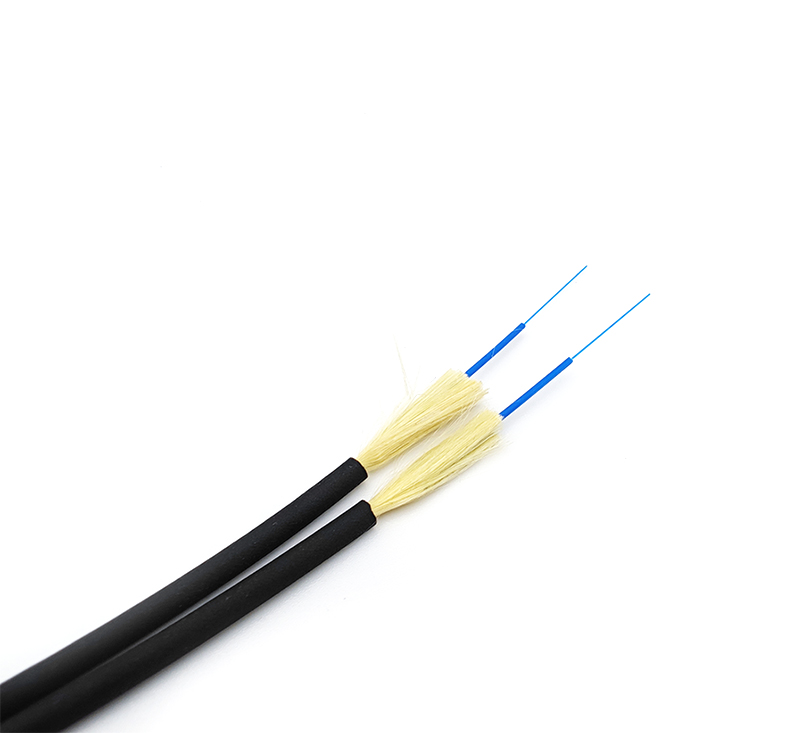

2. Optical fibers: Regular optical cable manufacturers generally use A-grade fiber cores from major manufacturers. Some cheap and inferior optical cables usually use C-grade and D-grade fibers and smuggled fibers of unknown origin. This kind of optical fiber comes from various sources. Longer, usually faded from moisture, and multi-mode fibers are often mixed with single-mode fibers. Generally, small factories lack the necessary testing equipment to distinguish the quality of the fibers. Because the human eye cannot identify such optical fibers, the common problems encountered in the construction process are: narrow network bandwidth and short transmission distance; asymmetrical size, which cannot be connected with fiber pigtails; lack of flexibility of optical fibers, and the situation of coiled fibers It will break at the next turn.

3. Strengthen the steel wire: The steel wire of the regular manufacturer's outdoor optical cable has to be pickled and phosphated, and the surface is dark gray. Such steel wire does not increase the hydrogen loss, does not corrode, and has high compressive strength after being cabled. Inferior optical cables are generally replaced by iron wires or aluminum wires. The identification method is very easy. The surface is milky white, and it can be freely bent in the hand. The optical cable produced with such a steel wire has a large hydrogen loss, and the two sides of the hanging optical fiber box will corrode and crack after a long time.

4. Steel armor: Regular production enterprises use longitudinally bundled steel strips with wear-resistant coatings on both sides, and poor-quality optical cables use ordinary white iron sheets, usually only one side has been treated for rust prevention.

5. Loose tube: The loose tube of the optical fiber installed on the optical cable should be made of PBT raw materials. Such a tube has high compressive strength, no deformation, and aging resistance. Inferior optical cables generally use PVC as the casing. The diameter of the casing is very thin. When you pinch it, it will be flat and folded when you bend it. It is a bit like a plastic straw for drinking soda.

6. Fiber paste: The fiber paste in the outdoor optical cable can avoid the air oxidation of the optical fiber. Due to the moisture entering into the anti-moisture, etc., the fiber paste used for the inferior optical fiber is very small, which seriously affects the life of the optical fiber.