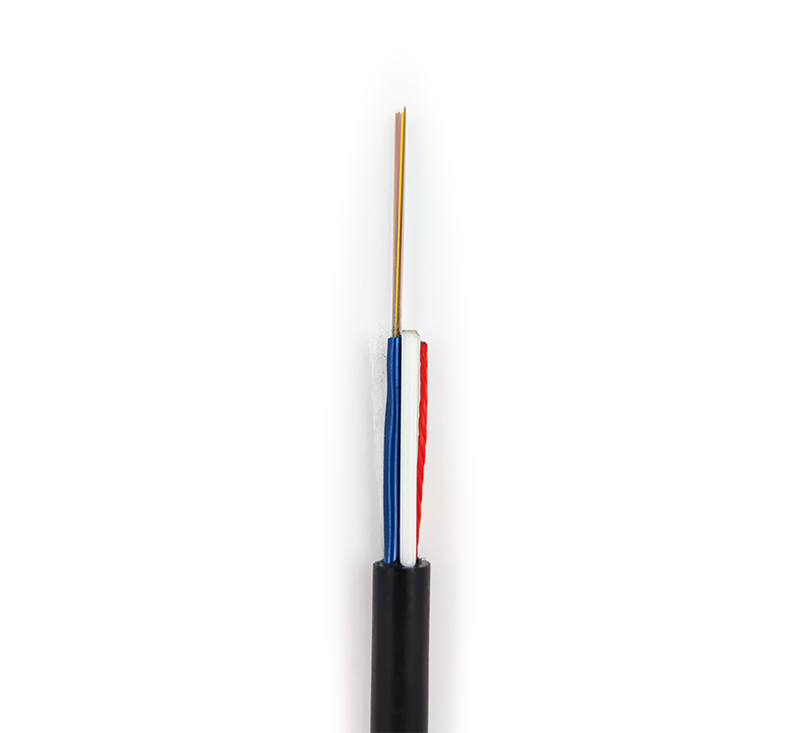

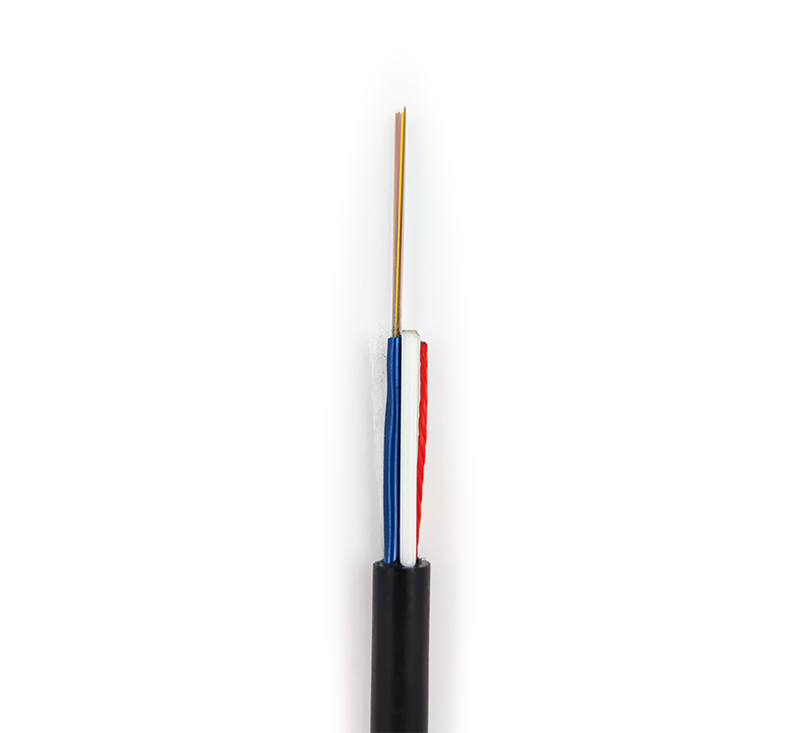

The formation of the excess length of the optical cable mainly comes from the secondary coating and the cabling process, which together determine the size of the excess length of the optical cable. The secondary coating process is the most important process for adjusting the excess length and excess length of the optical cable. It can achieve the purpose of adjusting the excess length by adjusting other process parameters. Figure 1 ROSENDAHL secondary coating machine, which is used to discuss the formation process of the excess length of the optical cable in the secondary coating.

The optical fiber is released from the pay-off frame with a certain pay-off tension, enters the main machine extrusion system through the oil gun, and then enters the pulley through the hot water tank for cooling. During this process, the optical fiber moves in a straight line. Because the optical fiber paste has thixotropy, the chemical bond is broken under shearing force, the viscosity of the fiber paste is reduced, and the fiber paste has good fluidity. The optical fiber is straightened in the hot water tank without forming excess length or negative Yu Chang. Since the optical fiber has a certain amount of stretching (generally <1%) when it is under force, on the other hand, the optical fiber is close to the inner side of the bundle tube when the optical fiber is pulled by the wheel, and the relative bundle tube is longer than the optical fiber. In the cold water tank section is the main stage of forming excess length, due to the large shrinkage of the bundle tube during cooling, the excess length is formed, which offsets the previous negative excess length to form the required excess length.

The layered optical cable is also twisted to form a certain excess length, and the bundle tube is longer than the optical cable. Give the fiber enough stretch window. The relative length of the bundle tube can be calculated by the following formula:

L=1000/cosα(1)

Where L is the length m of the cable bundle tube per kilometer, and α is the twisting angle of the optical cable.

tgα=π(φ1+φ2)/W(2)

φ1 is the diameter of the reinforcement, φ2 is the diameter of the bundle tube, and W is the cable pitch.

It can be seen from the above two formulas that the actual bundle length of each kilometer of optical cable is longer than that of the optical cable, and the longer part can be used to provide part of the excess length, plus the excess length formed by the two sets, the two together form all the excess length of the optical cable. long enough for the cable to stretch.

For the central bundled tube type optical cable, since there is no excess length of the cabled part, the excess length should be larger during the secondary plastic wrapping. Sufficient stretch window is provided for the fiber optic cable. Therefore, the corresponding excess length of the bundle tube is set for the optical cable of different purposes.